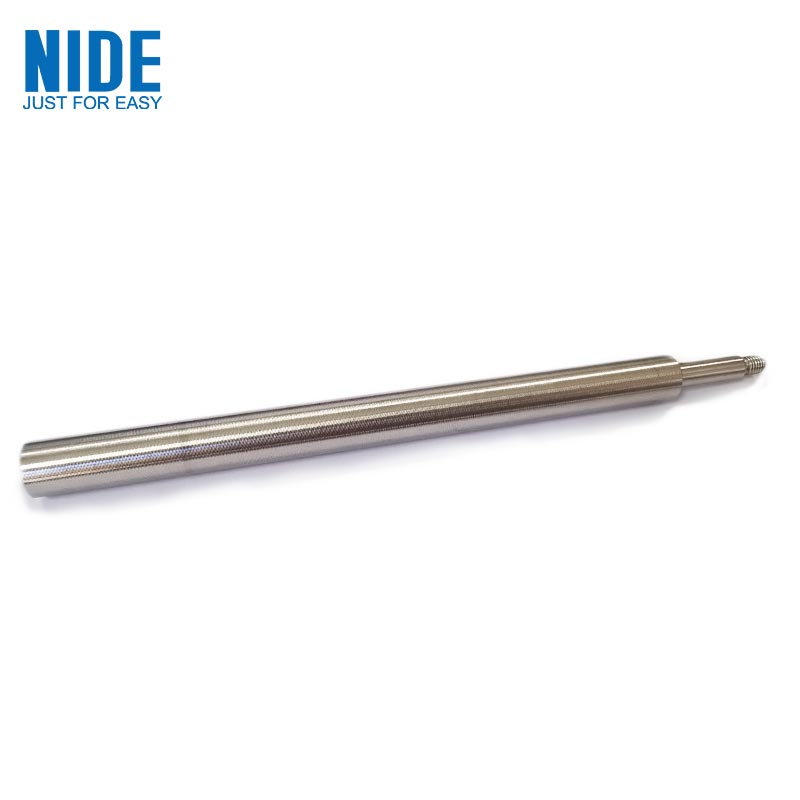

Mai Haɗa Abinci Motar Shafts Linear Shaft

Aika tambaya

Mai Haɗa Abinci Motar Shafts Linear Shaft

Tushen motar mu yana da halaye na ƙarfin ƙarfi, ƙayyadaddun ƙayyadaddun buƙatu, juriya mai kyau, juriya mai kyau da ingantaccen aiki don tabbatar da aiki da rayuwar sabis na motar.

Ƙirƙirar madaidaicin mashin ɗin motar yana buƙatar kulawa da ƙayyadaddun buƙatun kayan, fasahar sarrafawa da inganci don tabbatar da cewa inganci da aikin shaft ɗin sun dace da buƙatun amfani. Gabaɗaya la'akari da abubuwan da ke gaba:

1. Zaɓin kayan abu: Ƙaƙwalwar motar yawanci ana yin ta da ƙarfe mai ƙarfi mai ƙarfi ko bakin karfe. Zaɓin zaɓin abu yana buƙatar ƙaddara bisa ga dalilai kamar yanayin da ake amfani da mahaɗin, kaya, da girman shaft.

2. Fasahar sarrafa shaft: Fasahar sarrafa mashin ɗin yakan haɗa da hanyoyi masu yawa kamar juyawa, niƙa, da hakowa. Waɗannan hanyoyin haɗin suna buƙatar sarrafa daidaiton mashin ɗin don tabbatar da cewa diamita, tsayi, zagaye da sauran nau'ikan shaft sun cika buƙatun.

3. Maganin saman: Domin inganta yanayin yanayin da kuma rayuwar sabis na motar motar, ana buƙatar jiyya na gabaɗaya. Alal misali, ana iya amfani da fashewar yashi, goge-goge, electroplating da sauran hanyoyin da za a iya amfani da su don magance saman shaft.

4. Taruwa da dubawa: Bayan an gama yin aikin katako, ana buƙatar taro da dubawa. Lokacin haɗuwa, ya kamata a ba da hankali ga matsayi da dacewa na shaft don tabbatar da cewa za'a iya shigar da shaft daidai a cikin mahaɗin. A lokacin dubawa, wajibi ne don gudanar da bincike kan girma, taurin, da runout axial don tabbatar da cewa ingancin shaft ya dace da bukatun.

Sigar Samfura (Takaddamawa)

|

Bakin karfe |

C |

St |

Mn |

P |

S |

A ciki |

Cr |

Mo |

Ku |

|

SUS303 |

≤0.15 |

≤1 |

≤2 |

≤0.2 |

≥0.15 |

8 ~ 10 |

17-19 |

≤0.6 |

|

|

Saukewa: SUS303CU |

≤0.08 |

≤1 |

≤2.5 |

≤0.15 |

≥0.1 |

6 ~ 10 |

17-19 |

≤0.6 |

2.5 ~ 4 |

|

SUS304 |

≤0.08 |

≤1 |

≤2 |

≤0.04 |

≤0.03 |

8 ~ 10.5 |

18-20 |

||

|

Saukewa: SUS420J2 |

0.26 ~ 0.40 |

≤1 |

≤1 |

≤0.04 |

≤0.03 |

0.6 |

12 ~ 14 |

||

|

SUS420F |

0.26 ~ 0.40 |

0.15 |

≤1.25 |

≤0.06 |

≥0.15 |

0.6 |

12 ~ 14 |

Cikakken Bayani